Watertown Water Bears

2021 NYWEA competition was the Water Bears first in person competition.

2021 WEFtec Chicago. Watertown Water Bears claim 1st place in the Lab and Process Control event resulting in an overall 2nd place finish in Division III

2022 NYWEA Spring Conference. Water Bears claim 1st place Process Control, 2nd place Lab, finishing in 3rd place overall

2022 WEFtec New Orleans. Water Bears place 2nd in Process event for Division II

2023 NYWEA/NEWEA Joint Spring Conference Water Bears place 2nd in Laboratory and 3rd in Process

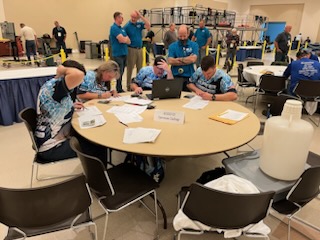

2023 WEFtec Chicago. Water Bears place FIRST in Laboratory event, 2nd in Process event for Division II, and won the spirit award for best team photo. 2023 was a record year for Operation Challenge as there were 55 teams competing from 6 different nations. Water Bears competed in division II consisting of 23 teams.

.jpg)

photo credit Derek Martin 3A city of Watertown Process Worker I

At the 2024 WEFTEC in New Orleans, the Water Bears secured 1st place in the Laboratory event and 2nd place in the Process event for Division II. The 2024 competition set a record for Operations Challenge participation and New York representation, with 56 teams from five nations. Competing in Division II against 19 teams, the Water Bears were one of six teams representing New York. Across all divisions, New York teams claimed victory in the most events among all Operations Challenge competitors.

Operations Challenge is multi-day international competition designed to showcase the team’s knowledge and skills in Process Control, Laboratory Analysis, Pump Maintenance, Collection System Repair, and Safety.

The Process Control event is a written test and a computer simulator of a water resource recovery facility; team members must manipulate the facility to comply within the given limits of a specific scenario. The process event prepares an operator for all levels of their license requirements.

The City of Watertown Pollution Control Facility is also a certified lab with NYS Environmental Laboratory Approval Program (ELAP). The events tested on during the Laboratory Event are completed on a daily basis by our water resource recovery professionals.

During the Maintenance Event the team learns valuable techniques and critical thinking. The teams have to Lock Out Tag Out (LOTO) a control panel and pump, then trouble shoot the panel and repair a pump. Giving all members of the Operation Challenge teams experiences with LOTO, electrical work, and learning the internals of a pump.

Teams enter a staged permit required confined space to rescue a worker who has been overcome by dangerous gases present in our sewer systems and repair the cause of the sewer lines emitting the gases during the Safety Event. Increasing awareness of potential hazards associated with day-to-day operations of our water resource recovery facilities.

Competitors must reprogram a composite sampler while the rest of the team repair a broken sewer line by installing another section of pipe with an Inserta T and flexible couplings only utilizing hand tools. The Collection Event teaches participants time management, tool preparation, and job efficiency because this is the fastest and most exciting out of all five events. Collection typically is completed in less than 2 minutes.

The Water Bear team members have expanded their knowledge base, experiences, and overall became more well-rounded water resource recovery operators since their involvement with Operations Challenge. Our municipality has gained experience, network connections, new equipment, media exposure, and recognition from our elected officials for the work we are doing at our treatment plant.

The ultimate benefit we attained from having a team in Operations Challenge is the teamwork that comes along with competing. Teamwork we have witnessed is a two-part package. Not only do we as competitors have teamwork within the Operations Challenge community but, we have improved teamwork within our facility.

Operation Challenge is more than just old and new friends getting together a couple times a year to show off their skills, it’s a family! We mentor, learn, assist, and challenge each other to be the best water resource recovery operators we can be.